Filter chambers & systems

NEES Filtersysteme

Filter chambers / systems

NEES filters are robust solutions for circulating and cleaning polluted or abrasive liquids or liquid mixtures. The NEES Pumpen filter chambers are distinguished by very low pressure losses.

|

|

Filter chamber

|

|

Filter chamber

|

|

Material: PP |

|

Materials: PP and PVDF |

NFK-10-3 and 20-3

Material: PP

Flow rate: 1,5 to 4,5m³/h

Filter input: d25/DN20

Filter output: d25/DN20

NFK-10-7 and 20-7

Materials: PP and PVDF

Flow rate: 7 bis 21m³/h

Filter input: d32/DN25

Filter input: d32/DN25

NEES filter chambers are used to reliably and safely filter chemically aggressive or highly corrosive fluids and wastewater. Ever-growing demands on the filter chambers, high runtime expectations, as well as highest product safety: We are constantly working to improve and redefine existing standards.

100% product safety for people and equipment is a principle we will not compromise in the sophisticated design of our pumps. Thanks to their innovative, proven construction, NEES filter chambers of the NFK-10-3 and NFK-20-3 series are very robust, versatile and absolutely dry-run safe. These filter chambers are characterized by extremely low pressure losses.

You will find a list of the available filter media and freely selectable filter cartridges in the PDF.

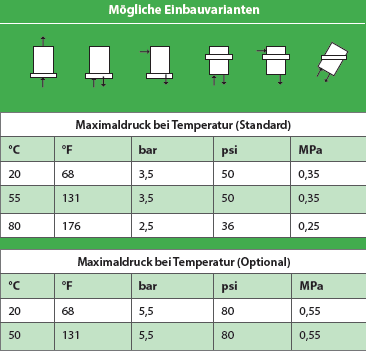

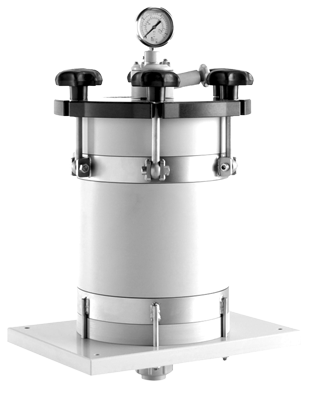

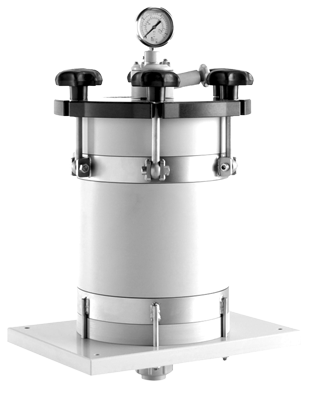

Filter chamber

NFK-10-3 and NFK-20-3

| Materials: | PP |

| Flow rate: | 1,5 to 4,5m³/h |

| Filter input: | d25/DN20 |

| Filter output: | d25/DN20 |

Some typical applications:

Electroplating, etching equipment, textile industry, process engineering, water and wastewater treatment, cleaning equipment, food and beverage industry

Characteristics:

- Easy to service

- Low pressure loss

- Fast and easy filter change

- No bottom seal necessary (welded filter chamber floor)

- Suitable for plate filters (thin/thick paper, tissue slices), fold bag filters, bag filters or filter cartridges (max. Ø 70mm)

- Robust and compact construction

- PP material: temperature up to max. +80 °C

- External closure parts made of stainless steel (1.4571 / V4A)

- Connection for rigid piping (inserts made of PP or CPVC)

- Cover made of glass fibre reinforced PP (higher strength)

- Large range of variants

Optionally available:

- External closure parts made of titanium or nickel-coated

- Pressure gauge

- Hose connectors

- PP feet

- Mounting plate according to customer requirements

- Use for "single open end" cartridges

- Filter basket insert for bag filter or microfibre

NEES filter chambers are used to reliably and safely filter chemically aggressive or highly corrosive fluids and wastewater. Ever-growing demands on filter chambers, high runtime expectations, and highest product safety: These challenges drive us to constantly improve and redefine the existing standards. 100% product safety for people and equipment is a principle we will not compromise in the sophisticated design of our pumps. Thanks to their innovative, proven design, NEES filter chambers of the NFK-10-7 and NFK-20-7 series are very robust, versatile and absolutely dry-run safe. These filter chambers are characterized by extremely low pressure losses.

You will find a list of the available filter media and freely selectable filter cartridges in the PDF.

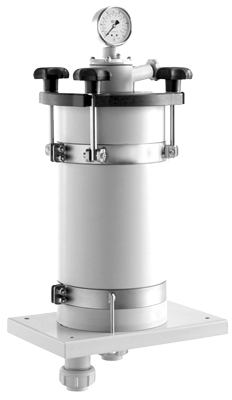

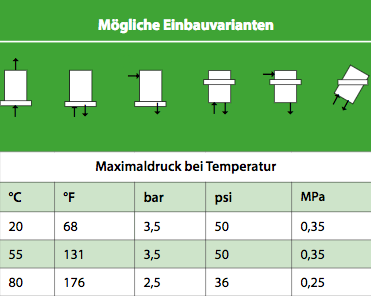

Filter chamber

NFK-10-7 and NFK-20-7

| Materials: | PP and PVDF |

| Flow rate: | 7 to 21m³/h |

| Filter input: | d32/DN25 |

| Filter output: | d32/DN25 |

Some typical applications:

Electroplating, pickling and etching equipment, textile industry, process engineering, water and wastewater treatment, , cleaning equipment, food and beverage industry

Characteristics:

- Easy to service

- Low pressure loss

- Fast and easy filter change

- No bottom seal necessary (welded filter chamber floor)

- Suitable for plate filters (thin/thick paper, tissue slices), fold bag filters, bag filters or filter cartridges (max. Ø 70mm)

- Robust and compact construction

- PP material: temperature up to max. +80 °C

- Complete with pressure gauge and bleeder valve

- PVDF material: temperature up to max. +100 °C

- External closure parts made of forged and thick-walled stainless steel (1.4571 / V4A)

- Connection for rigid piping (inserts made of PP, PVDF or CPVC)

- Cover made of glass fibre reinforced PP (higher strength)

- Large range of variants

Optionally available:

- External closure parts made of titanium or nickel-coated

- Hose connectors

- PP feet (adjustable height)

- Mounting plate according to customer requirements

- Use for "single open end" cartridges

- Filter basket insert for bag filter or microfibre