Vertical centrifugal pump, submersible pump

Vertical centrifugal pump, submersible pump

V-2.2 to V-8.8

|

V-5 to V-41

|

V-90 to V-260

|

V-2.2 to V-8.8

|

V-5 to V-41

|

V-90 to V-260

|

Submersible pump

|

||||||||||||

Some typical applications:

Optionally available:

|

Characteristics:

|

NEES Chemie vertical pumps are used to reliably and safely transfer chemically aggressive or highly corrosive fluids and wastewater. Ever-growing demands on the pumps, high runtime expectations, enhanced energy efficiency, and highest product safety: These challenges drive us to constantly improve and redefine the existing standards. 100% product safety for people and equipment is a principle we will not compromise in the sophisticated design of our pumps. Thanks to their innovative and proven construction, vertical submersible pumps of the NEES V-2.2-5 to V-8.8-9 series are very energy efficient, robust, versatile and absolutely dry-run safe. The compact design saves valuable space in your plant. The fluid is transferred to the discharge nozzle via a piping system inside the pump body. The symmetrical arrangement around the pump impeller achieves the following advantages: low-vibration operation, insensitivity to solid particles and very low pressure losses inside the pump. Solid matter can also be directly transferred from pump sumps, wells, containers or basins.

|

NEES Chemie vertical pumps are used to reliably and safely transfer chemically aggressive or highly corrosive fluids and wastewater. Ever-growing demands on the pumps, high runtime expectations, enhanced energy efficiency, and highest product safety: These challenges drive us to constantly improve and redefine the existing standards. 100% product safety for people and equipment is a principle we will not compromise in the sophisticated design of our pumps. Thanks to their innovative and proven construction, vertical submersible pumps of the NEES V-2.2-5 to V-8.8-9 series are very energy efficient, robust, versatile and absolutely dry-run safe. The compact design saves valuable space in your plant. The fluid is transferred to the discharge nozzle via a piping system inside the pump body. The symmetrical arrangement around the pump impeller achieves the following advantages: low-vibration operation, insensitivity to solid particles and very low pressure losses inside the pump. Solid matter can also be directly transferred from pump sumps, wells, containers or basins.

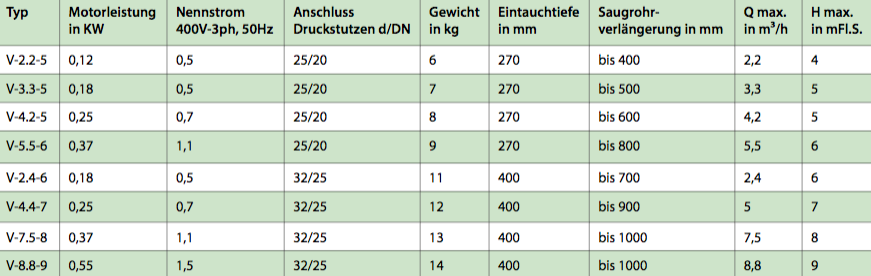

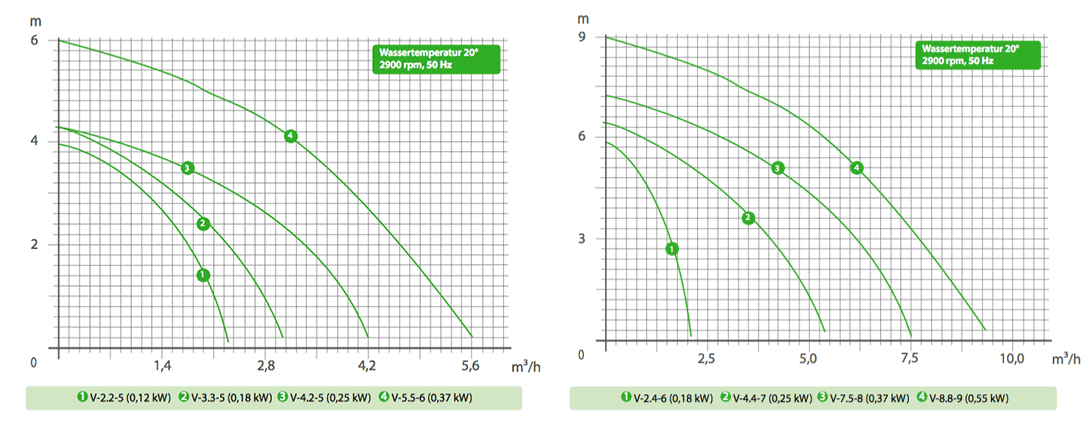

Submersible pump

V-2.2-5 to V-8.8-9

| Materials: | PP and PVDF |

| Immersion depths: | 270 and 400mm |

| Flow rate: | 1 to 10m³/h |

| Delivery head: | up to 9mLC |

| Engine power: | 0,12 to 0,55kW |

Some typical applications:

Gas and fume scrubbers, filtration of liquids , production of semiconductors and solar cells, use in coating plants , operation of water treatment plants, purging applications , PCB processing equipment, electroplating equipment, general mixing and circulation tasks, redox flow applications, disinfection equipment.

- All wetted parts made of PP or PVDF (no metal-to-liquid contact)

- Without intermediate bearing, therefore absolutely safe to run dry

- Motor with multi-range voltage (also 50/60 Hz operation possible)

- Special paint and fan cowls made of plastic for use in aggressive atmosphere

- Reinforced engine ball bearings and extended motor shaft for stability and longevity

- Abrasion-free, therefore suitable for high purity applications

- Compact and energy efficient design

- Low maintenance, therefore cost-effective operation

- Compression fittings available with inserts made of PP, PVDF and CPVC

Optionally available:

- Suction extensions

- Intermediate filter

- Hose connectors

- Special connections

- FIP fittingsn

Submersible pump

|

||||||||||||

Some typical applications:

Optionally available:

|

Characteristics:

|

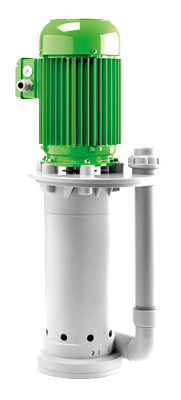

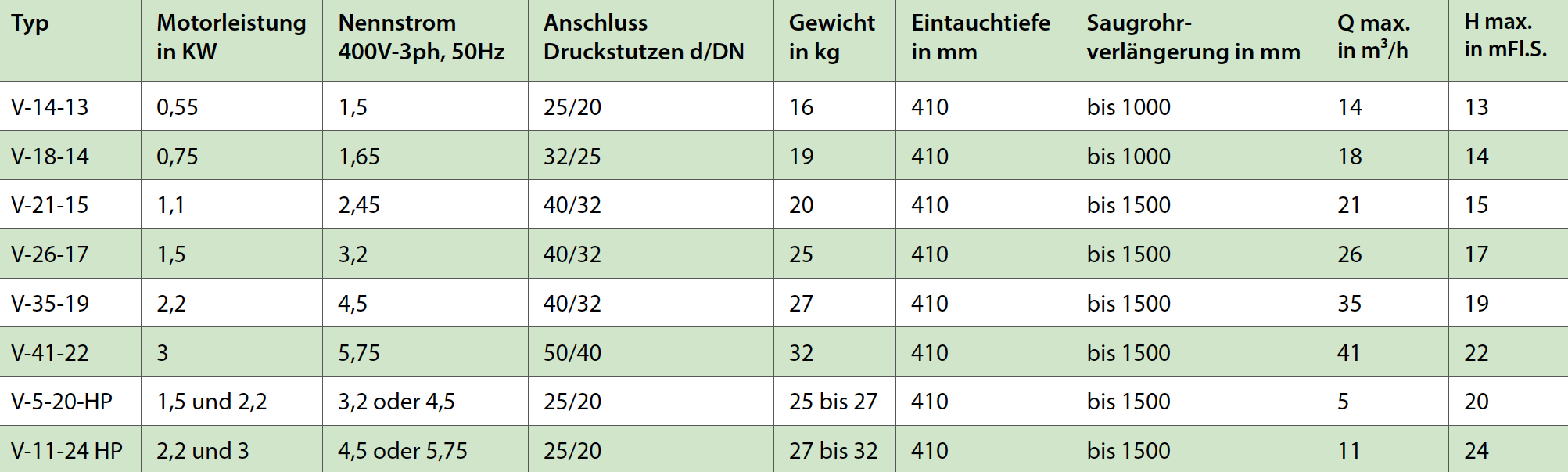

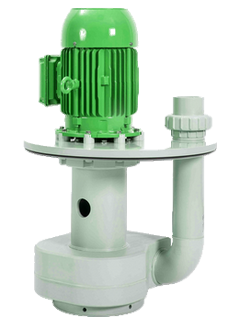

Nees Chemie vertical pumps are used to reliably and safely transfer chemically aggressive or highly corrosive fluids and wastewater. Ever-growing demands on the pumps, high runtime expectations, enhanced energy efficiency, and highest product safety: These challenges drive us to constantly improve and redefine the existing standards. 100% product safety for people and equipment is a principle we will not compromise in the sophisticated design of our pumps. Thanks to their innovative and proven construction, vertical submersible pumps of the Nees V-5 to V-41 series are very energy efficient, robust, versatile and absolutely dry-run safe. Low-vibration operation, insensitivity to solid particles and very low pressure losses distinguish this pump. The pump can also transfer solid matter directly from pump sumps, wells, containers or basins in wet and dry installation.

|

Nees Chemie vertical pumps are used to reliably and safely transfer chemically aggressive or highly corrosive fluids and wastewater. Ever-growing demands on the pumps, high runtime expectations, enhanced energy efficiency, and highest product safety: These challenges drive us to constantly improve and redefine the existing standards. 100% product safety for people and equipment is a principle we will not compromise in the sophisticated design of our pumps. Thanks to their innovative and proven construction, vertical submersible pumps of the Nees V-5 to V-41 series are very energy efficient, robust, versatile and absolutely dry-run safe. Low-vibration operation, insensitivity to solid particles and very low pressure losses distinguish this pump. The pump can also transfer solid matter directly from pump sumps, wells, containers or basins in wet and dry installation.

Submersible pump

V-5 to V-41

| Materials: | PP and PVDF |

| Immersion depth: | 410 mm |

| Flow rate: | 1,5 to 41 m³/h |

| Delivery head: | up to 25 m LC at 50 Hz; up to 32 m LC at 60 Hz |

| Engine power: | 0,55 to 3 kW |

Some typical applications:

Gas and fume scrubbers, filtration of liquids, production of semiconductors and solar cells, use in coating plants, operation of water treatment plants, purging applications, PCB processing equipment, electroplating equipment, general mixing and circulation tasks, exhaust scrubber for ships, redox flow applications, disinfection systems.

Characteristics:

- All wetted parts are made of PP or PVDF (no metal-to-liquid contact)

- Without intermediate bearing, therefore absolutely safe to run dry

- Motor with multi-range voltage

- Special paint for use in aggressive atmosphere

- Reinforced engine ball bearings and extended motor shaft for stability and longevity

- Abrasion-free, therefore suitable for high purity applications

- Energy efficient design

- Low maintenance, therefore cost-effective operation

- The variant made of the material PVDF is carbon fibre reinforced. This reduces the thermal expansion at higher temperatures and ensures high energy efficiency.

- Compression fittings available with inserts made of PP, PVDF and CPVC

Optionally available:

- Suction extensions

- Intermediate filter

- Hose connectors

- Customised mounting flange

- Vapour barrier

- FIP fittings

- Special connections

- Dry installation (outdoor installation) next to the container

- HP variant with high pressure

- Special designs are always possible

Submersible pump

|

||||||||||||

Some typical applications:

Optionally available:

|

Characteristics:

|

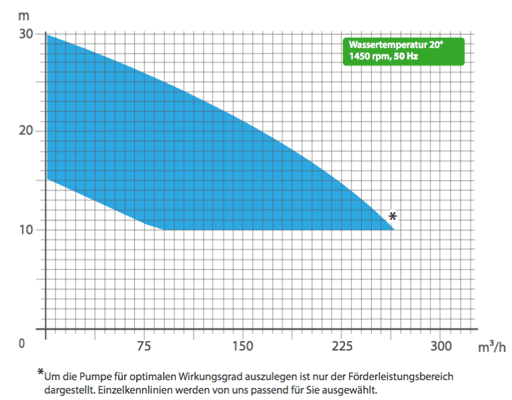

NEES Chemie vertical pumps are used to reliably and safely transfer chemically aggressive or highly corrosive fluids and wastewater. Ever-growing demands on the pumps, high runtime expectations, enhanced energy efficiency, and highest product safety: These challenges drive us to constantly improve and redefine the existing standards. 100% product safety for people and equipment is a principle we will not compromise in the sophisticated design of our pumps. Thanks to their innovative and proven construction, vertical submersible pumps of the NEES V-90-15 to V-260-29 series are very energy efficient, robust, versatile and absolutely dry run safe. Low-vibration operation, insensitivity to solid particles and very low pressure losses distinguish this pump. Solid matter can also be directly transferred from pump sumps, wells, containers or basins.

|

NEES Chemie vertical pumps are used to reliably and safely transfer chemically aggressive or highly corrosive fluids and wastewater. Ever-growing demands on the pumps, high runtime expectations, enhanced energy efficiency, and highest product safety: These challenges drive us to constantly improve and redefine the existing standards. 100% product safety for people and equipment is a principle we will not compromise in the sophisticated design of our pumps. Thanks to their innovative and proven construction, vertical submersible pumps of the NEES V-90-15 to V-260-29 series are very energy efficient, robust, versatile and absolutely dry run safe. Low-vibration operation, insensitivity to solid particles and very low pressure losses distinguish this pump. Solid matter can also be directly transferred from pump sumps, wells, containers or basins.

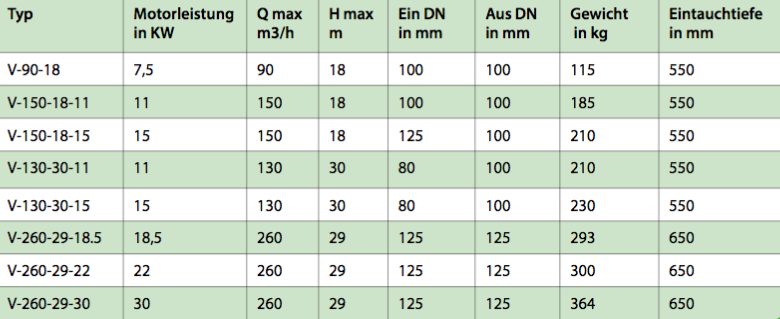

Submersible pump

V-90-15 to V-260-29

| Material: | PP |

| Immersion depths: | 550 and 650mm |

| Flow rate: | 30 to 260m³/h |

| Delivery head: | up to 30mLC |

| Engine power: | 7,5 to 30kW |

Some typical applications:

Gas and fume scrubbers, liquid filtration, semiconductor and solar cell production, coating equipment, chemical plants, water treatment plants, rinsing applications, PCB processing equipment, electroplating equipment, general mixing and recirculation tasks, exhaust gas scrubbers for ships, disinfection equipment.

Characteristics:

- All wetted parts made of PP (metal-to-liquid contact)

- Abrasion-free, therefore suitable for high purity applications

- Without intermediate bearing, therefore absolutely safe to run dry

- Robust construction for stability and longevity

- Motor 400/690 V-3ph with thermal winding protection

- Temperature up to +80 °C

- Vapour barrier

- Special paint for use in aggressive atmosphere

- Energy-efficient design • Low maintenance, therefore cost-effective operation

- FKM (Viton) O-rings

- Suction-side NPT thread for connection of intake manifold or suction strainer

- Pressure-side flange DIN 2501 - PN 10

Optionally available:

- Suction extensions

- Motor fan cover with protective cover

- Suction strainer

- EPDM O-rings

- Horizontal discharge nozzle

- Mounting flange according to customer requirements

- Flat gasket for tank installation