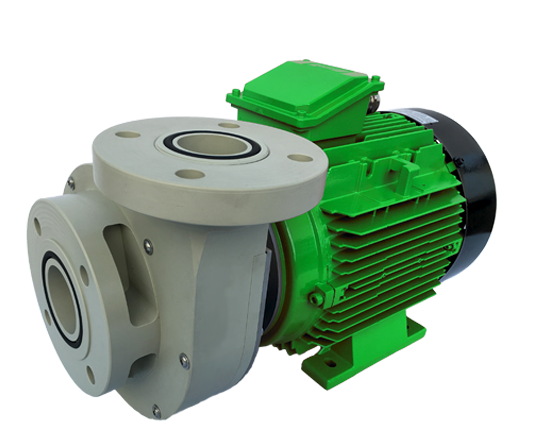

Centrifugal pump with mechanical seal, normal suction

Centrifugal pump with mechanical seal, normal suction

|

Centrifugal pump with mechanical seal, normal suction

|

||||||||||||||||

Some typical applications:

Optional:

Optionally available:

|

Characteristics:

|

NEES mechanical seal pumps have universal applications. Our "all-rounder" is often used when chemically aggressive or corrosive fluids and wastewater have to be handled reliably and safely. Ever-growing demands on the pumps, high runtime expectations, enhanced energy efficiency, as well as highest product safety: We are constantly working to improve and redefine existing standards. 100% product safety for people and equipment is a principle we will not compromise in the sophisticated design of our pumps. Thanks to their innovative and proven construction, horizontal NEES mechanical seal pumps in the compact block design of the HMS series are very energy-efficient, robust and versatile. Low-vibration operation, insensitivity to solid particles and very low pressure losses distinguish this pump. The pump can also transfer metal particles.

|

NEES mechanical seal pumps have universal applications. Our "all-rounder" is often used when chemically aggressive or corrosive fluids and wastewater have to be handled reliably and safely. Ever-growing demands on the pumps, high runtime expectations, enhanced energy efficiency, as well as highest product safety: We are constantly working to improve and redefine existing standards. 100% product safety for people and equipment is a principle we will not compromise in the sophisticated design of our pumps. Thanks to their innovative and proven construction, horizontal NEES mechanical seal pumps in the compact block design of the HMS series are very energy-efficient, robust and versatile. Low-vibration operation, insensitivity to solid particles and very low pressure losses distinguish this pump. The pump can also transfer metal particles.

![]() Centrifugal pump with mechanical seal, normal suction HMS-Series.pdf

Centrifugal pump with mechanical seal, normal suction HMS-Series.pdf

Centrifugal pump with mechanical seal, normal suction

| Materials: | PP, PVDF and stainless steel A4 |

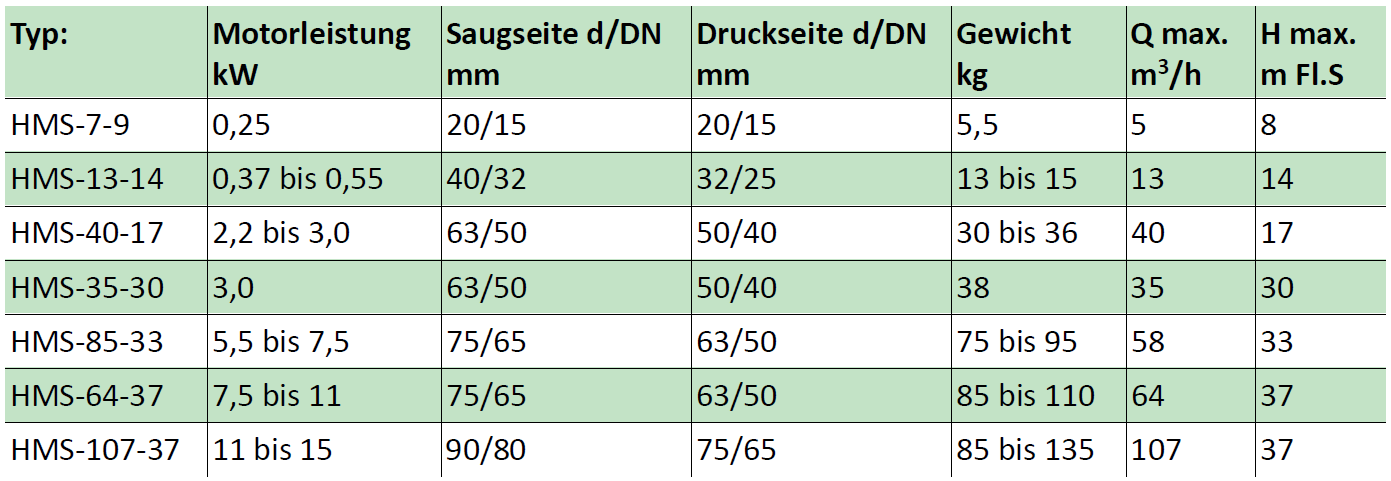

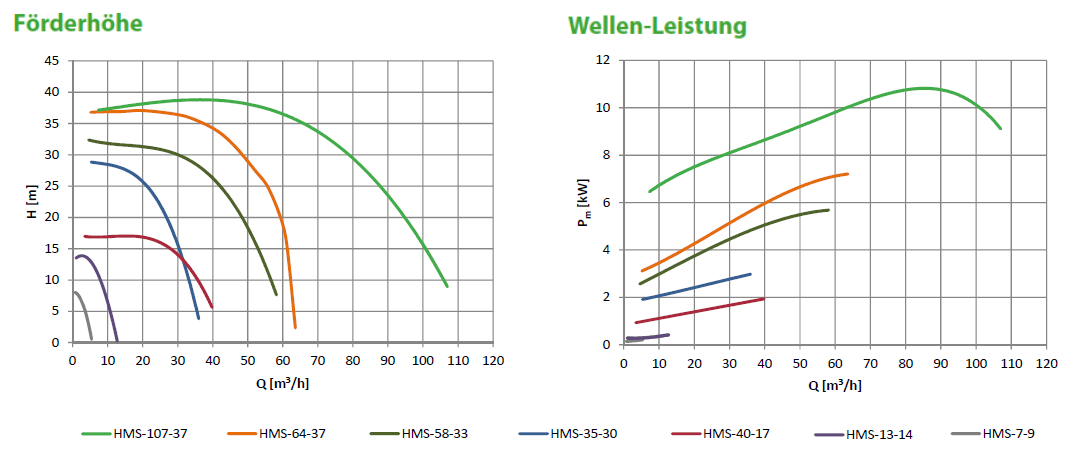

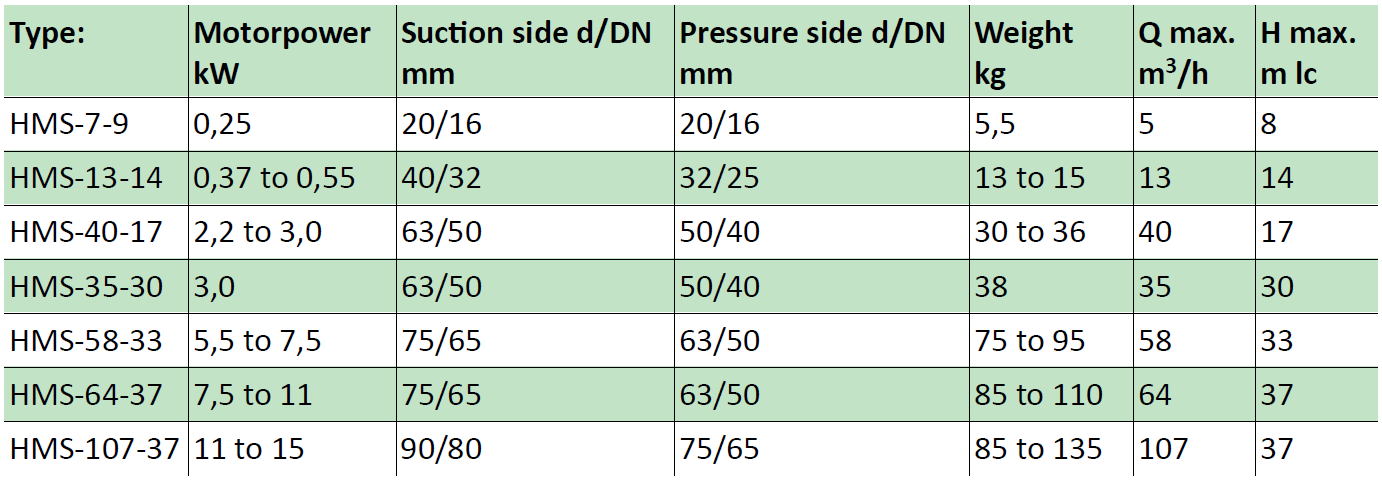

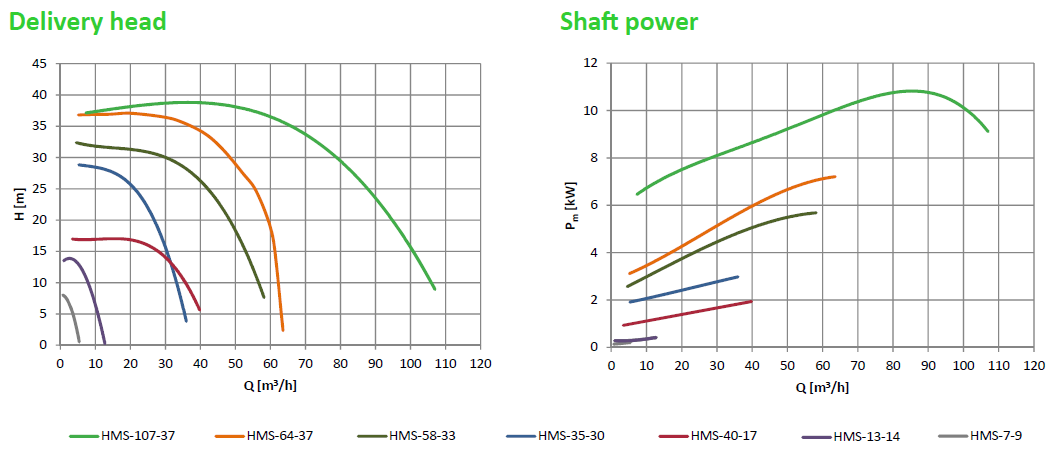

| Flow rate: | 0,5 to 65m³/h |

| Delivery head: | up to 37mLC |

| Motor power: | 0,25 to 15kW |

| Energy efficiency class: | IE3 |

Some typical applications:

Production of semiconductors and solar cells, gas and exhaust air scrubbers, filtration of liquids, use in coating plants, operation of water treatment plants, purging applications, PCB processing equipment, electroplating equipment, general mixing and circulation tasks, redox flow applications, disinfection systems, pumping toxic fluids.

Characteristics:

- Low maintenance due to almost wear-free mechanical seal

- Delivery of metallic particles possible

- Easy to install

- Compact design (surface optimized)

- Efficiency optimized up to 63%

- Motors prepared for frequency converter operation

- Motoren für Frequenzumrichter- Betrieb vorbereitet

- Pumps up to DN50 optionally with thread & flange connection

- From DN50 with flange connection

- 100% test with certificate

Optionally available:

- UL / CSA / ATEX versions

- Compact drives (motor with frequency converter)

- Flange and hose connections

- Union nuts and piping accessories

- Special connections

- Special designs are always possible