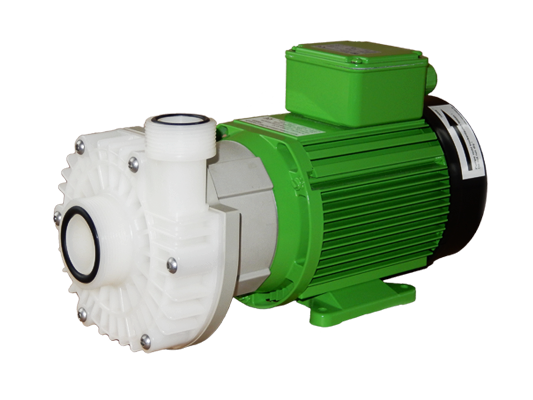

Magnetically coupled centrifugal pump, normal suction

Magnetically coupled centrifugal pump, normal suction

|

Magentically coupled centrifugal pump, normal suction NHMD-Series |

||||||||||||||||

Some typical applications: Optional:

Optionally available:

|

Characteristics:

|

NEES Chemie magnetic pumps are used to reliably and safely transfer chemically aggressive or highly corrosive fluids and wastewater. Ever-growing demands on the pumps high runtime expectations, enhanced energy efficiency, as well as highest product safety: We are constantly working to improve and redefine existing standards. 100% product safety for people and equipment is a principle we will not compromise in the sophisticated design of our pumps. Thanks to their innovative and proven construction, horizontal NEES magnetic pumps of the NHMD series are very energy-efficient, robust and versatile. Low-vibration operation, insensitivity to solid particles and very low pressure losses distinguish this pump. The pump can also transfer solid matter..

|

NEES Chemie magnetic pumps are used to reliably and safely transfer chemically aggressive or highly corrosive fluids and wastewater. Ever-growing demands on the pumps, high runtime expectations, enhanced energy efficiency, as well as highest product safety: We are constantly working to improve and redefine existing standards. 100% product safety for people and equipment is a principle we will not compromise in the sophisticated design of our pumps. Thanks to their innovative and proven construction, horizontal NEES magnetic pumps of the NHMD series are very energy-efficient, robust and versatile. Low-vibration operation, insensitivity to solid particles and very low pressure losses distinguish this pump. The pump can also transfer solid matter.

![]() Magnetically coupled centrifugal pump, normal suction NHMD-Series.pdf

Magnetically coupled centrifugal pump, normal suction NHMD-Series.pdf

Magnetically coupled centrifugal pump, normal suction

NHMD-Serie

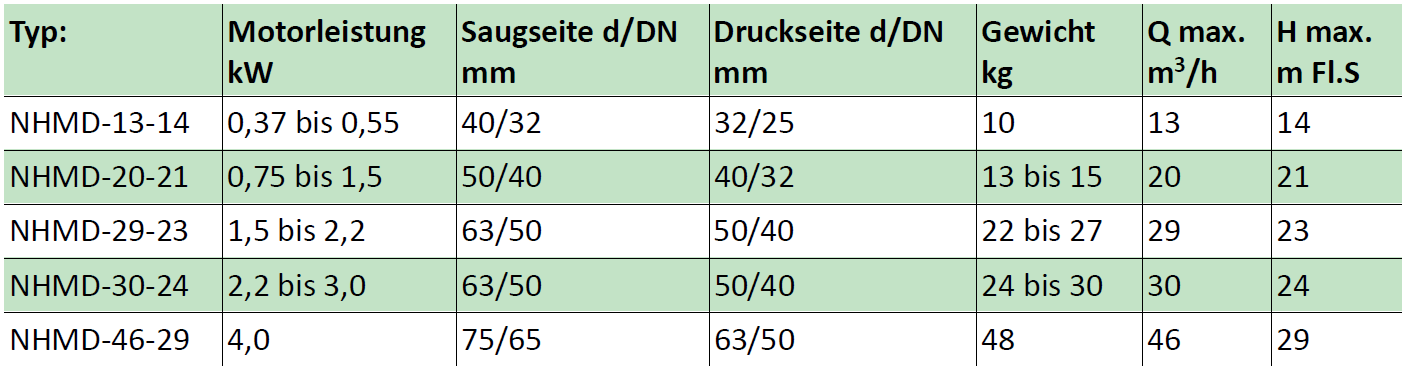

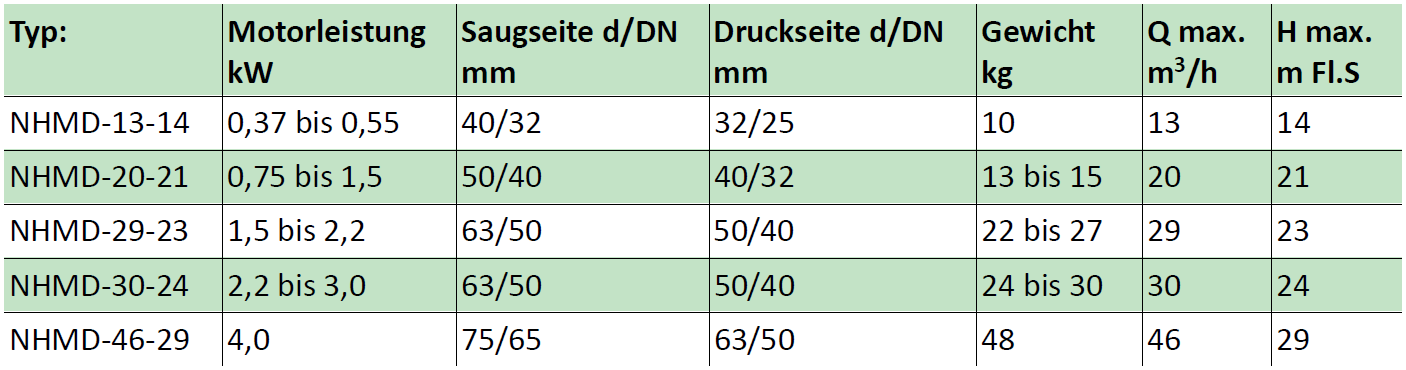

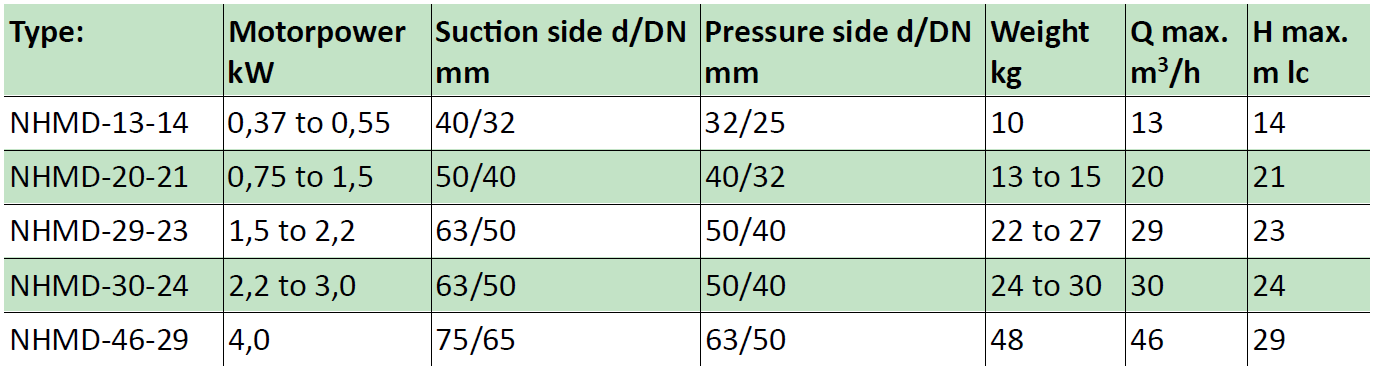

| Materials: | PP, PVDF and high performance polymer (PEEK ECTFE) |

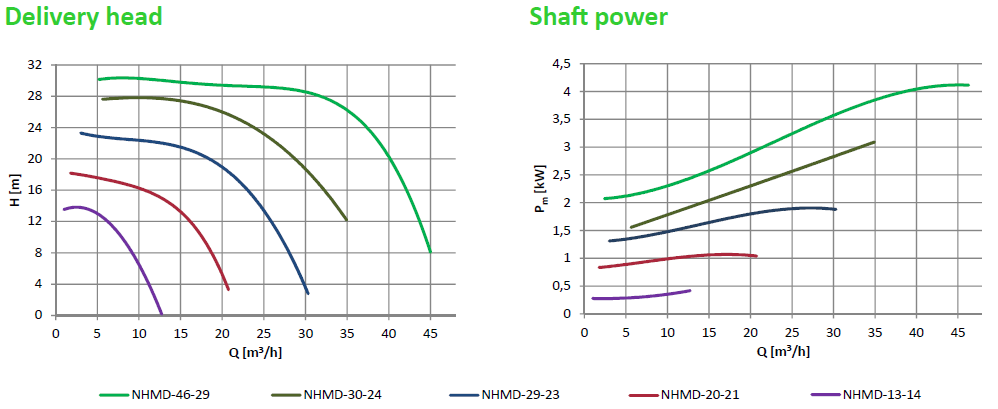

| Flow rate: | 0,5 to 46 m³/h |

| Delivery head: | up to 29 m LC |

| Motor power: | 0,55 to 4 kW |

| Energy efficiency class:: | IE3 |

Some typical applications:

Production of semiconductors and solar cells, gas and exhaust air scrubbers, filtration of liquids, use in coating plants, operation of water treatment plants, purging applications, systems for PCB processing, electroplating equipment, general mixing and circulation tasks, redox flow applications, disinfection systems, pumping toxic fluids.

Characteristics:

- All wetted parts are made of PP, PVDF or high performance polymers (PEEK compound) - no metal-to-liquid contact

- Depending on application and plain bearing materials, dry running can last several minutes

- Motor with multi-range voltage

- Special paint for use in aggressive atmosphere

- Not damaged, even if used in the wrong direction of rotation

- Abrasion-free, therefore suitable for high purity applications

- Energy efficient design

- Hermetically sealed

- Motor according to IE3

Optionally available:

- Elastomer of EPDM (standard), FKM or FFKM

- Welding flange bushings

- Hose nozzles

- Union nuts

- Special connections

- Slide bearing material pairing combination: SiC/PTFE carbon fibre reinforced (standard) or SiC/SiC

- UL/CSA versions

- Special designs are always possible